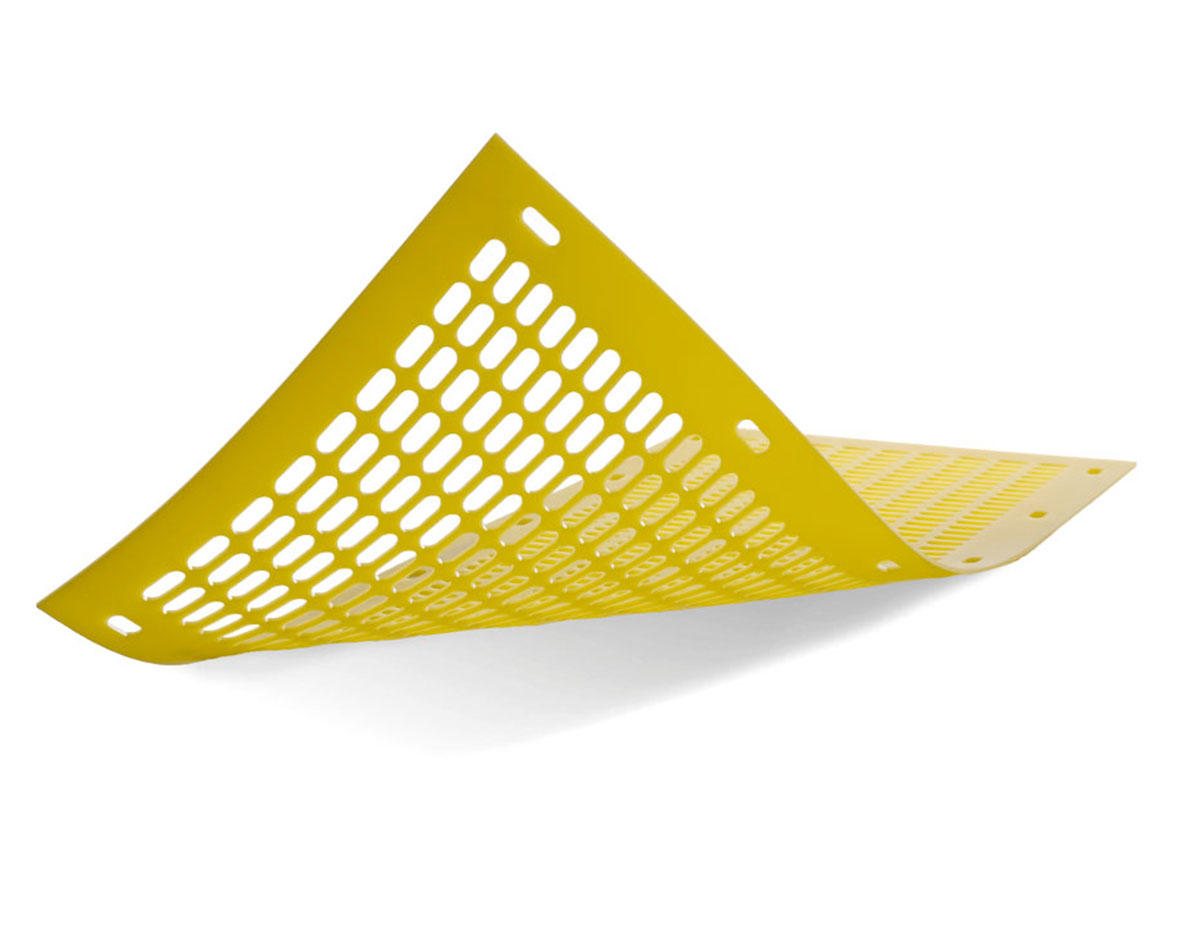

SCREEN MATS WITH SCREW FASTENINGS

Suitable for all common screening machines

FLEXIMAT PERFECTION®

Specially designed for demanding applications

Thanks to its outstanding resistance to mineral fats and oils, chemicals, acids, alkalis and hydrolysis as well as its excellent physical properties, Fleximat PERFECTION® is the first choice for demanding chemical applications. Also suitable for working with high temperatures (up to +100°C).

Areas of application for FLEXIMAT PERFECTION®

- Highly abrasive materials in the sand and gravel industry (e.g. sand with a high quartz content)

- Highly abrasive materials in the iron and steel industry (e.g. iron ore and coke)

- High temperatures

Technical data

| Color | Yellow |

| Length x width | 4000 x 250/345/355 mm |

| Material | Polyurethane |

| Shore hardness | FD 90 Shore A +/- 3° Shore A |

| Chemical basis | Polyester hot-casting system |

| Characteristics | High-quality cast polyurethane system with very good physical properties and excellent chemical resistance |

| Special advantages | Very good resistance to mineral fats and oils, resistant to hydrolysis, acids and alkalis (pH value 2-12 to 60 °C), lightfast (no darkening under UV influence) |

| Durability | Very good chemical resistance and very good physical properties, high dynamic load capacity, low abrasion |

| Operating temperature | In continuous operation up to approx. 100 °C (dry), briefly up to approx. 120 °C, depending on chemical attack up to approx. 80 °C |

| Service life | Up to 6,300 hours |

| Perforations | All common shapes and dimensions as well as custom-made products – More Infos |

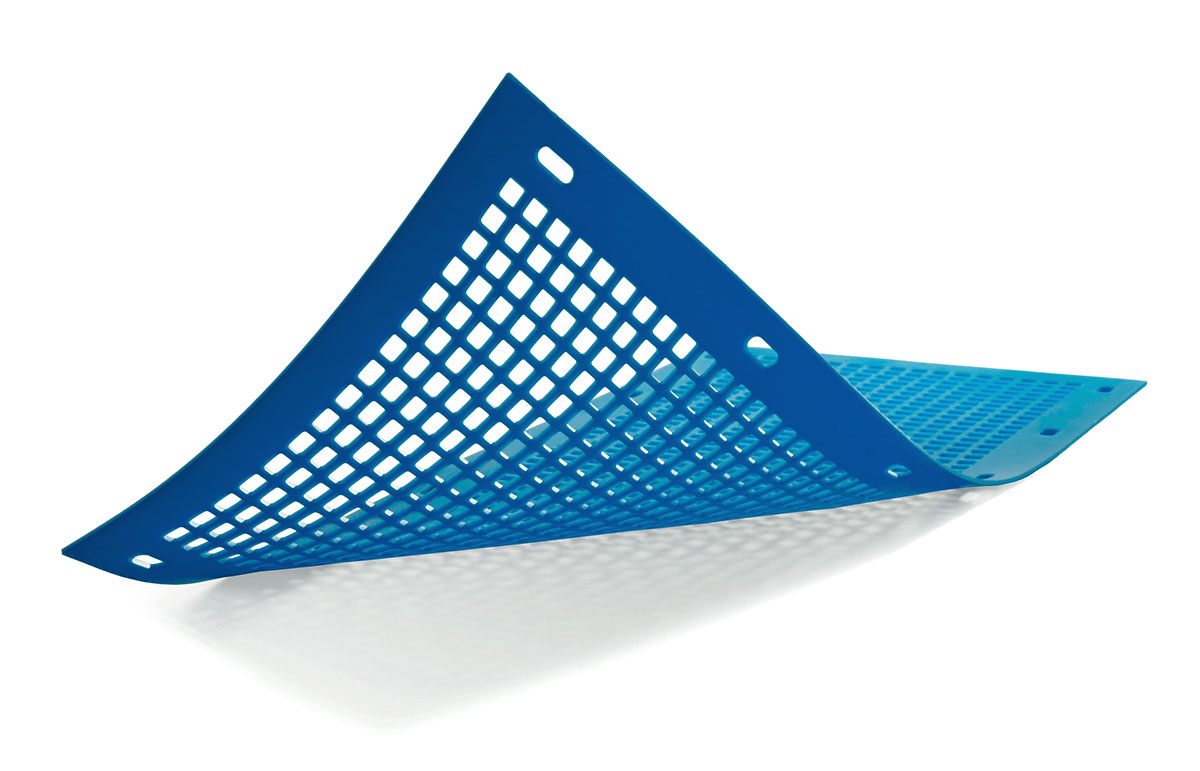

FLEXIMAT PERFECTION-D®

Highly resistant to high temperatures

In addition to a wide range of resistances, Fleximat PERFECTION-D® offers even better resistance to heat and high temperatures. The screen mat easily withstands temperatures of up to 130 °C in continuous operation, and temperatures of up to 150 °C are also possible for short periods.

Areas of application for FLEXIMAT PERFECTION-D®

- High-temperature applications in the iron and steel industry

- Abrasive, very hot materials (e.g. sinter, coke and slag)

Technical data

| Color | Signal blue |

| Length x width | 4000 x 250/345/355 mm |

| Material | Polyurethane |

| Shore hardness | FD 90 Shore A +/- 3° Shore A |

| Chemical basis | Polyester hot-casting system |

| Characteristics | High-quality cast polyurethane system with very good physical properties with excellent chemical resistance |

| Special advantages | Very good resistance to mineral fats and oils, resistant to hydrolysis, acids and alkalis (pH value 2-12 up to 60 °C), lightfast (no darkening under UV influence) |

| Durability | Very good chemical resistance with very good physical properties, high dynamic load capacity, low Abrasion |

| Operating temperature | In continuous operation up to approx. 130 °C (dry), briefly up to approx. 150 °C, depending on chemical attack up to approx. 95 °C |

| Service life | Up to 5,000 hours |

| Perforations | All common shapes and dimensions as well as custom-made products – More Infos |

- Multiple Resistances

- Continuous operation at temperatures up to +130°C

- UP TO 5,000 HOURS OF SERVICE LIFE

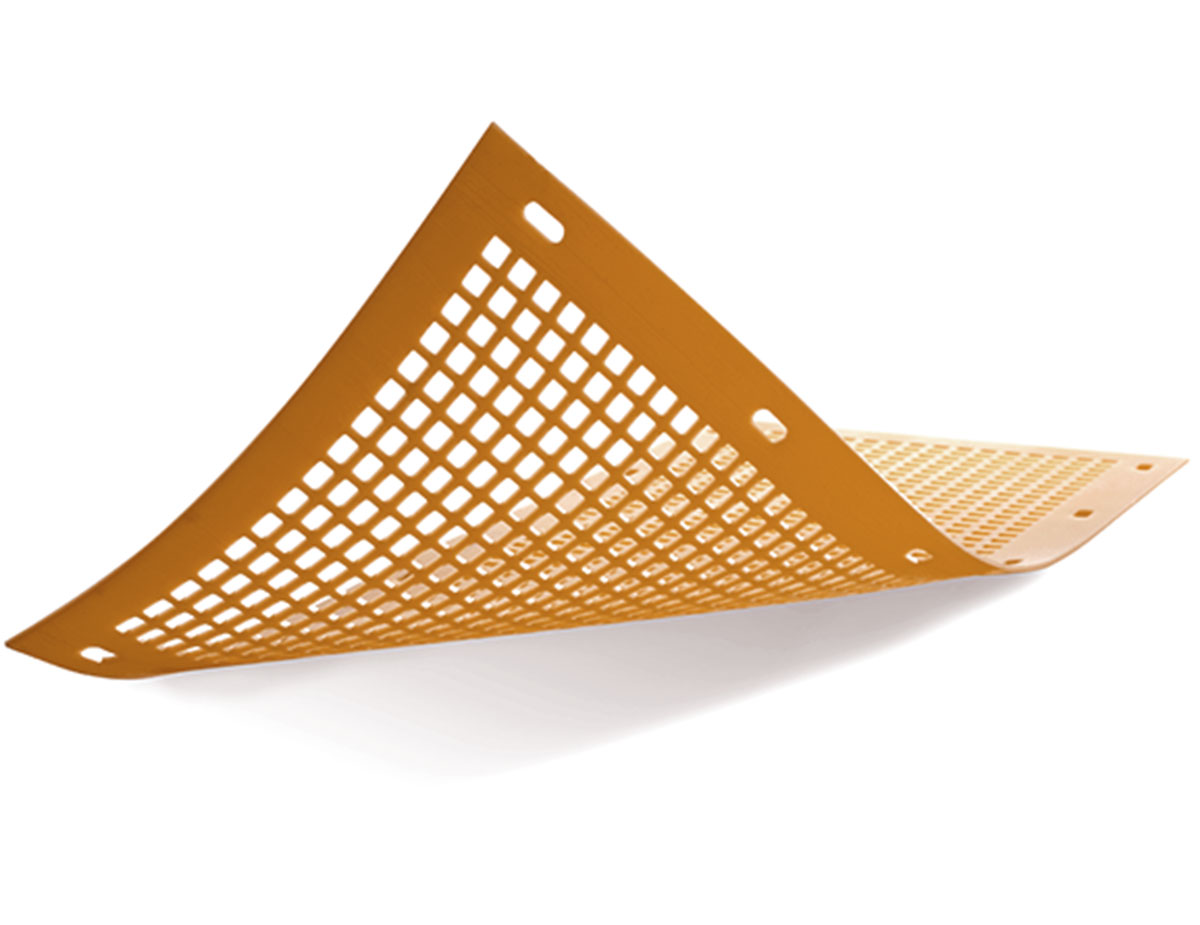

FLEXIMAT PREMIUM®

Licensed formula for exceptional quality

High dynamic load capacity and wear resistance as well as extensive resistance to mineral fats and oils over a wide temperature range (-20°C – 100°C): FLEXIMAT PREMIUM® meets even the highest demands thanks to the Vulkollan formula and the polyester hot-casting system licensed and patented by Bayer AG.

Areas of application for FLEXIMAT DELUXE®

- Sand, gravel and crushed stone

- Iron and steel industry

- Recycling industry

Technical data

| Color | ochre yellow to brown |

| Length x width | 4000 x 250/345/355 mm |

| Material | Vulkollan |

| Shore hardness | FD 93 Shore A +/- 3° Shore A |

| Chemical basis | Polyester hot-casting system licensed and patented by Bayer AG |

| Characteristics | Cast polyurethane system for the highest demands, especially in terms of resilience. Excellent physical properties. Oldest and best-known polyurethane recipe. |

| Special advantages | Highly dynamically resilient. Overall very balanced, excellent mechanical properties over a wide temperature range. Very high wear resistance. High abrasion and alternating bending strength. Very low permanent deformation. Constant modulus of elasticity from -20° C to +80° C. |

| Durability | Very good resistance to mineral fats and oils. Low swelling in glycol. |

| Operating temperature | In continuous operation up to approx. 100° C (dry). Short-term up to approx. 120° C. Very good properties in cold temperatures (down to -20° C). |

| Service life | Up to 6,000 hours |

| Perforations | all common shapes and dimensions |

- LICENSED BAYER AG SYSTEM

- EXCELLENT MECHANICAL PROPERTIES

- UP TO 6,000 HOURS OF SERVICE LIFE

ALWAYS THE RIGHT PERFORATED PIECE FOR YOUR SCREEN MAT

With years of experience, continual innovation, and a commitment to excellence, FLEXIMAT is dedicated to meeting even the most unique customer needs. Our screen mats, available in nearly every perforation type, are crafted with precision and can be custom-made on request.

Perforation Types:

| Elongate hole | Gap widths from 0.3 mm |

| Square hole | Hole sizes from 0.5 mm |

| Round hole | Diameters from 1.0 mm |

| Rectangular hole | Gap widths from 1.2 mm |

| Oval hole | Custom punching upon request |

| Unpunched | Blind screen mats and end pieces |

View our full perforation table for current specifications.